Why induction motor has high starting current?

Induction motors draw high starting current because the minimal rotor field at startup causes high impedance and lagging flux, combined with the need for high starting torque. This causes much higher current flow during startup compared to normal operation.

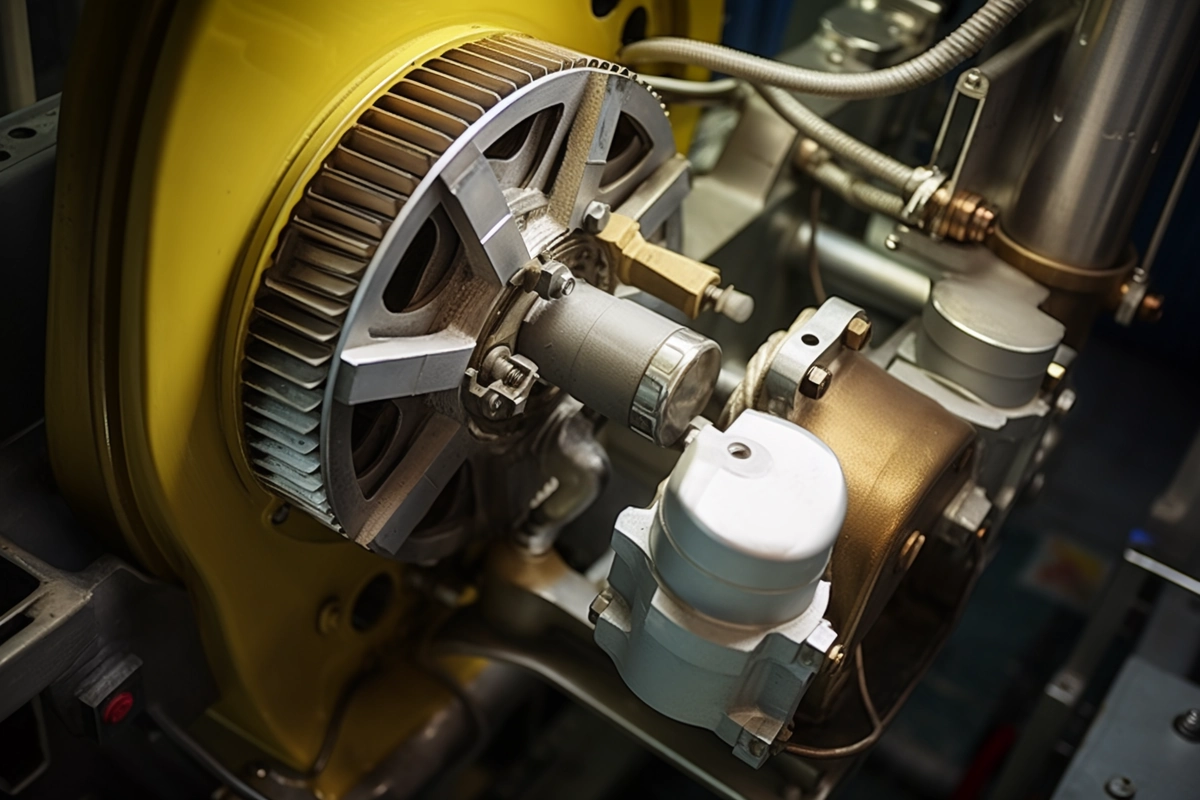

Induction motors are widely used in various industrial and commercial applications due to their reliability and efficiency. However, one common characteristic of induction motors is their high starting current. In this essay, we will delve into the technological aspects behind this phenomenon, exploring the factors that contribute to high starting current in induction motors and the implications it has on motor operation.

Understanding Induction Motors

To comprehend the reasons for high starting current, it is crucial to have a fundamental understanding of induction motors. Induction motors work on the principle of electromagnetic induction, where a rotating magnetic field is generated, inducing current in the rotor. This interaction creates torque, enabling the motor to start and operate.

Factors Influencing Starting Current

-

Rotor Resistance: Induction motors typically have low resistance in their rotor windings. During the starting phase, this low resistance causes a surge in current as the motor tries to establish the rotating magnetic field.

-

Inrush Current: Induction motors possess a high inrush current at startup due to the initial magnetizing of the motor's core and the charging of the stator winding. This inrush current contributes significantly to the total starting current.

-

Back EMF and Rotor Inductance: As the motor accelerates and the rotor current increases, a back electromotive force (EMF) is induced, opposing the applied voltage. The rotor's inductance, in combination with the back EMF, results in a higher starting current.

Implications of High Starting Current

-

Voltage Drop: The high starting current causes a voltage drop in the power supply system. This voltage drop can affect the performance of other connected equipment, leading to potential operational issues.

-

Thermal Stress: The high starting current results in increased heat generation within the motor windings. This thermal stress can negatively impact the motor's insulation system, potentially reducing its lifespan and reliability.

-

Power Quality: The inrush current drawn by induction motors during startup can cause power quality issues in the electrical distribution system, including voltage sags and harmonic distortion.

Mitigation Techniques

To mitigate the challenges associated with high starting current, several techniques are employed:

-

Soft Starters: Soft starters gradually ramp up the voltage supplied to the motor during startup, reducing the initial surge of current and minimizing the impact on the power supply system.

-

Variable Frequency Drives (VFDs): VFDs allow for controlled acceleration of the motor by adjusting the frequency and voltage supplied. This smooth starting process reduces the starting current and related issues.

-

Motor Design Optimization: Motor manufacturers can optimize the design of induction motors to reduce starting current by adjusting parameters such as rotor resistance, stator winding configuration, and magnetic core materials.

Conclusion

The high starting current in induction motors is primarily influenced by factors such as rotor resistance, inrush current, and back EMF. While this high starting current poses challenges such as voltage drop and thermal stress, various mitigation techniques, including soft starters and VFDs, can alleviate these issues. By understanding the technological aspects behind high starting current, engineers and motor designers can develop more efficient and reliable induction motors, ensuring optimal performance and longevity in industrial and commercial applications.

Leave a Comment