What causes a motor to stall?

A motor may stall due to various reasons such as overloading, low voltage, a damaged rotor, or a blocked rotor. It may also be due to a malfunctioning start capacitor or a faulty centrifugal switch, which can cause the motor to stop spinning or fail to start.

Sometimes, we may encounter the situation that the motor is blocked and cannot run normally when we use the motor, which will bring a lot of inconvenience to our production life, and in serious cases, the motor even has the risk of being burned out. In this article, we will discuss why the motor may be blocked.

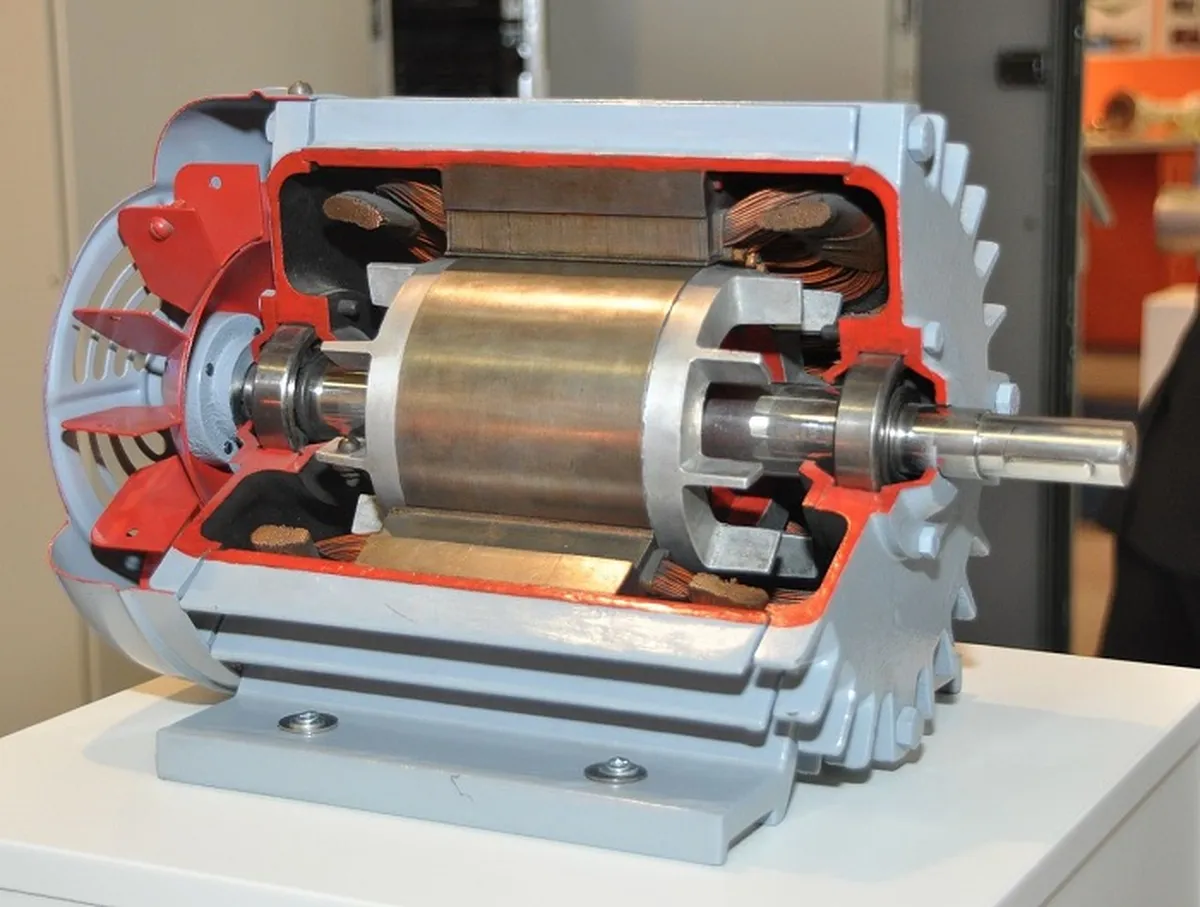

The working principle of the motor

A motor converts electrical energy into mechanical energy through the interaction of magnetic fields. When the motor is running, its coils are energized and a rotating magnetic field is generated. This magnetic field interacts with the permanent magnets on the rotor, causing the rotor to rotate. As long as power is supplied, the magnetic fields continue to interact, and the motor continues to run.

Causes of motor blockage

Overload or overheat

One of the most common causes of motor stalling is overload or overheating. If a motor is forced to run above its rated capacity for an extended period, it can easily cause the motor to overheat and lead to blocked rotation. This is because the maximum current when the motor is blocked can be up to 7 times the rated current. Excessive current can cause the temperature of the windings and bearings to exceed the safety limit, and once time the motor is blocked for too long, it will easily stop running.

Low voltage conditions

The motor requires a minimum operating voltage to generate the magnetic field needed to rotate the rotor. If the voltage falls below this threshold, the motor will not have enough power to overcome the load and will stall. Voltage drops can be caused by power supply problems, excessive voltage drops due to long wiring distances, or a load wire gauge that is too small.

Load increase

If an additional mechanical load is applied after the motor is running, more torque and power are required to overcome the additional load and maintain speed. If the load increases beyond the motor's capacity, its speed drops until the rotor simply cannot spin and stop.

Conclusion

In summary, the three main causes of motor stalling are primarily overheating, low voltage and excessive load. By monitoring the motor temperature and voltage, properly sizing the motor to the expected load, and avoiding extreme load changes during operation, stall problems can be largely prevented and motor reliability improved.

Leave a Comment