Selection knowledge of small AC motors

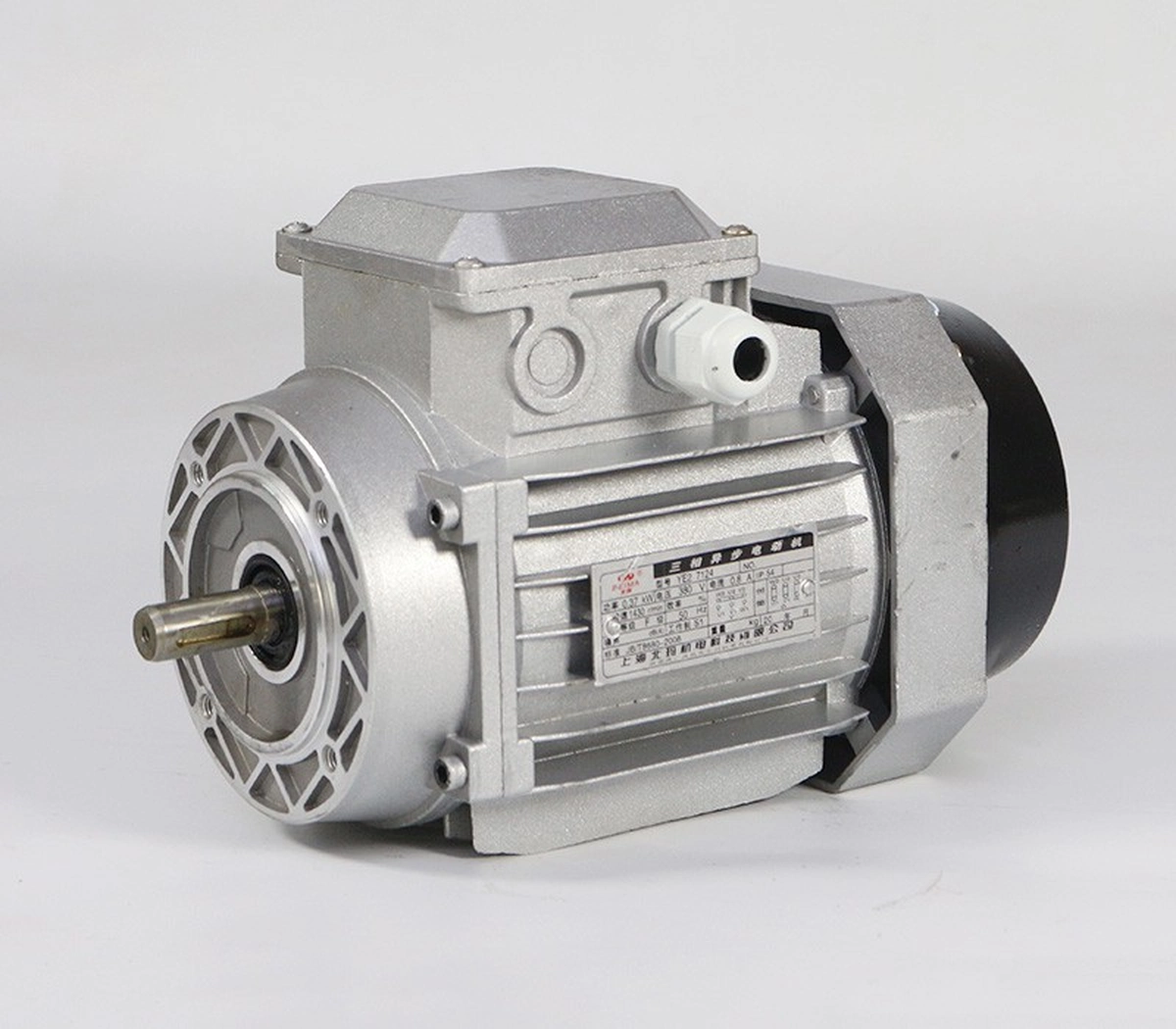

Compared with traditional motors, small AC motors are smaller, have lower power, but have higher speeds. They have many characteristics and application scenarios.

A small AC motor is a motor with small size, low power and high speed. They have many features and applications, and there are many factors to consider when choosing the right small AC motor.

- Reasonably select the type of motor based on the load nature and production process of the machinery, as well as the requirements for motor starting, braking, reversing, and speed regulation.

- According to the requirements of load torque, speed range, and frequency of starting, consider the temperature rise limit, overload capacity, and starting torque of the motor to select the power of the motor reasonably so as to achieve a reasonable power matching and strive for safety, reliability, and economy.

- According to the environmental conditions of the usage location, such as temperature, humidity, dust, rainwater, gas, corrosive substances, and explosive gas content, consider the necessary protection methods and select the protective structure type of the electric motor.

- Determine the voltage rating of the motor based on the voltage standard of the company's power grid and the requirements for power factor.

- Select the voltage level of the electric motor based on the maximum speed of the production machinery, the requirements for the power transmission speed control system, and the complexity of the mechanical deceleration.

- When selecting a motor, the price, construction cost, and operating cost of the product should be considered, aiming for the best overall economic benefits. For dry and clean environments, it is advisable to use an 'IP23' motor as much as possible. This type of motor is approximately 70% cheaper than a motor of the same capacity with an 'IP44' rating. Additionally, the manufacturing factory can save on materials. For continuous operation and high load rates, it is recommended to use high-efficiency motors to achieve energy savings and improve overall economic benefits.

- When selecting a motor, factors that affect installation, operation, and maintenance should be considered, with the aim of facilitating installation and maintenance and ensuring reliable operation.

- Standards and parameter concepts referred to when selecting motors:

- Operation mode and quota of the motor

- Operating conditions of the motor

- Temperature rise of the motor

- Dielectric performance of the motor

- Protection level of the motor casing

- Cooling methods for motors

- Structure and installation types of motors

- The noise limit of the motor

- Vibration limit of the motor

- Power rating of the motor

Leave a Comment