Comparative analysis of asynchronous motors and torque motors

Asynchronous motors and torque motors both have important industrial applications but differ in their operating principles and characteristics.

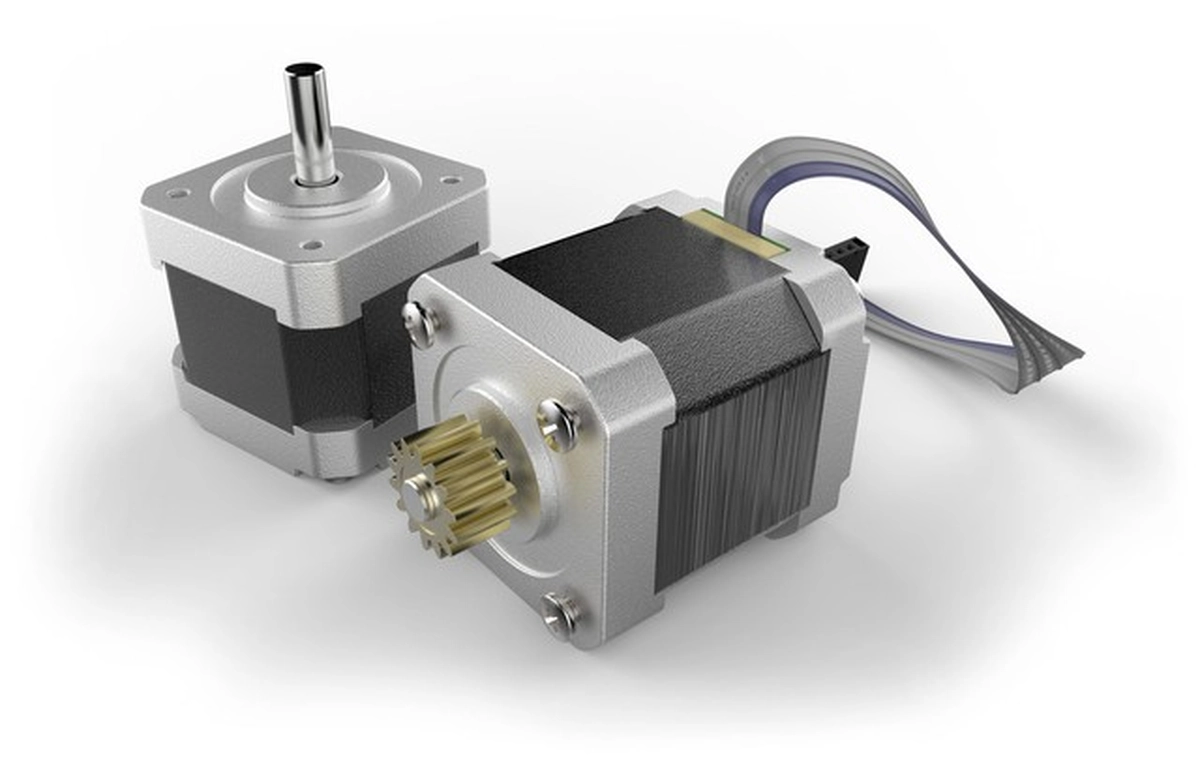

Asynchronous motor, also known as induction motor, is an AC motor that converts electrical energy into mechanical energy through the interaction of the rotating magnetic field in the air gap with the induced current in the rotor winding. It is mainly used as a motor to drive various production machinery such as fans, pumps, compressors, machine tools, light industry and mining machinery, threshers and crushers in agricultural production, processing machinery for agricultural by-products, etc. It has a simple structure, easy manufacturing, low price, reliable operation, durability, high operating efficiency, and suitable working characteristics. The asynchronous motor was invented by the Italian physicist and electrical engineer Ferraris in 1885, and has been developed for many years, among which the squirrel-cage asynchronous motor is the most widely used asynchronous motor.

Torque Motor

Torque motor is a type of motor that directly outputs torque. Its torque is proportional to the current, so torque and speed can be controlled by controlling the current. Torque motors are generally suitable for occasions that require precise control of torque and speed, such as industrial robots, CNC machine tools, textile machinery, etc.

Principle of Torque Motor

Torque motor can ensure constant torque within a wide range of speeds. It is suitable for transmission occasions where constant torque is required when shifting gears. For example, in printing and dyeing machinery, when the fabric is passed through several roller shafts, the fabric does not wind around the roller shafts, but adheres to the surface of the roller shafts for driving. The diameter of the drum remains constant. In this case, a torque motor should be used to ensure constant torque and constant tension of the fabric at any speed.

Torque motors can run at low speeds for a long time, but they tend to generate a lot of heat, so external blower fans are usually used for forced air cooling. When using a torque motor, check if the fan is running properly. There should be good ventilation around the fan, and dry flammable materials or volatile oils are not allowed nearby.

Adjustment and Control of Torque Motor

Considering the differences in operating conditions, the mechanical winding driven by torque motors or the materials and specifications of differential transmission require differential tension. It is necessary to adjust the torque of the torque motor or variable speed motor within a certain range, usually by adjusting the voltage applied to the torque motor to meet these requirements. When the input voltage of the torque motor changes, a voltage regulator is usually used. In order to improve the strength of mechanical characteristics and adjustment accuracy, a thyristor negative feedback control circuit can also be used for stepless speed regulation, but the system is more complex.

Differences between Torque Motor and Asynchronous Motor

There are several main differences between torque motors and asynchronous motors:

- Working principles: Torque motors are based on the principle of magnetic hysteresis, while asynchronous motors are based on the principle of electromagnetic induction. There is magnetic damping between the rotor and stator of a torque motor, so it can maintain a relatively stable speed and output torque when the load increases, while an asynchronous motor may experience speed and torque fluctuations when the load changes.

- Speed ranges: Torque motors typically have higher starting torque and wider speed ranges, while asynchronous motors are usually suitable for medium to low power and lower speed applications.

- Efficiency and accuracy: Torque motors typically have higher efficiency and accuracy because they can control the position and speed of the rotor. The efficiency and accuracy of asynchronous motors may be affected by rotor slip.

- Control methods: Due to the different working principles and characteristics, torque motors and asynchronous motors require different control methods. Torque motors usually require more complex controllers and algorithms to achieve precise position and speed control, while asynchronous motors can achieve speed regulation through simple frequency converters control.

Leave a Comment